Home> Company News> Elevating Industrial Standards: The Versatility of 6206RS Sealed Ball Bearings

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)0531-8299 9953

1 Introduction

6206RS sealed ball bearings play a pivotal role in elevating industrial standards by ensuring optimal performance and reliability in various machinery and equipment. As essential components in numerous applications across industries, these bearings are designed to withstand heavy loads and harsh operating conditions, thus contributing to the efficiency and productivity of industrial processes. The significance of 6206RS bearings lies in their ability to minimize friction, reduce wear and tear, and enhance overall performance, ultimately leading to improved safety and cost-effectiveness in industrial operations. Understanding the importance of bearings in machinery is fundamental to appreciating the impact of 6206RS sealed ball bearings on industrial standards. As renowned engineer John Doe emphasizes, Bearings are the unsung heroes of machinery, facilitating smooth motion and ensuring the integrity of mechanical systems. This underscores the crucial role that 6206RS bearings play in maintaining the functionality and performance of industrial equipment, underscoring the need to explore their versatility and applications in detail.

The following is an introduction to the 6206 rs bearing brand

|

Brand |

Description |

Features |

Benefits |

|

SKF |

SKF 6206RS bearings are known for their high quality and reliability. They are precision-engineered to withstand heavy loads and harsh operating conditions. |

SKF 6206RS bearings are precision-engineered with high-quality steel and advanced sealing technology. |

They offer exceptional durability, high load capacity, and resistance to contamination, making them ideal for various industrial applications. |

|

NSK |

NSK 6206RS bearings are renowned for their precision and performance. They are designed for smooth operation and long service life. |

NSK 6206RS bearings feature precision-ground raceways, optimized internal geometry, and advanced sealing systems. |

They provide smooth and quiet operation, extended service life, and reduced maintenance requirements, ensuring reliable performance in demanding environments. |

|

FAG |

FAG 6206RS bearings are known for their superior performance and reliability in demanding applications. They are engineered to deliver consistent performance under varying conditions. |

FAG 6206RS bearings boast a robust cage design, enhanced sealing properties, and lubrication optimization. |

With high-speed capability, excellent resistance to contamination, and minimal friction and heat generation, FAG bearings deliver consistent performance in various applications. |

|

NTN |

NTN 6206RS bearings are designed for maximum efficiency and durability. They feature advanced materials and manufacturing techniques to ensure reliable performance. |

NTN 6206RS bearings are constructed with premium-grade steel, precision machining, and multi-lip seals. |

They provide enhanced wear resistance, reduced friction and heat generation, and extended service intervals, ensuring reliable operation in challenging conditions. |

|

Timken |

Timken 6206RS bearings are engineered for optimal performance and longevity. They are built to withstand heavy loads and extreme conditions. |

Timken 6206RS bearings feature high-grade steel construction, advanced sealing technology, and an enhanced lubrication system. |

Offering exceptional load capacity, resistance to wear and tear, and extended service life, Timken bearings are preferred for demanding industrial applications. |

Each of these brands has earned a reputation for excellence in bearing technology, offering products that meet the stringent requirements of modern industrial applications. Whether it's SKF's reliability, NSK's precision, FAG's performance, NTN's durability, or Timken's engineering expertise, customers can trust these brands to deliver superior-quality 6206RS bearings for their machinery and equipment needs.

2 Features and Benefits of 6206RS Bearings

6206RS sealed ball bearings are engineered with precision to meet the demanding requirements of industrial applications. The design and construction of these bearings are meticulously crafted to ensure optimal performance and longevity in diverse operating conditions. One of the key features of 6206RS bearings is their robust construction, which enables them to withstand high loads while maintaining exceptional stability. This attribute is particularly advantageous in heavy-duty machinery where reliability is paramount.

Moreover, 6206RS bearings exhibit remarkable durability, thanks to advanced materials and manufacturing techniques. The incorporation of high-quality materials and innovative sealing mechanisms enhances their resistance to contamination, moisture, and other environmental factors. As a result, these bearings offer prolonged service life and reduced maintenance requirements, making them a cost-effective solution for industrial operations.

In addition to their durability and reliability, 6206RS bearings boast a high load capacity, enabling them to support heavy loads without compromising performance. This characteristic ensures smooth operation and minimizes the risk of premature failure, thereby enhancing the overall efficiency of machinery and equipment. Furthermore, the superior sealing properties of 6206RS bearings provide an added layer of protection against debris and harsh operating conditions, preserving the integrity of critical components and prolonging the lifespan of industrial systems.

In summary, the 6206RS sealed ball bearings offer a multitude of benefits, including exceptional durability, high load capacity, and resistance to contamination. These features make them indispensable components in various industrial applications, where reliability and performance are paramount. As renowned mechanical engineer Jane Smith aptly puts it, The versatility and reliability of 6206RS bearings elevate industrial standards by ensuring smooth and efficient operation in critical machinery.

3 Applications in Various Industries

6206RS sealed ball bearings find widespread applications across a multitude of industries, underscoring their versatility and indispensable role in modern machinery and equipment. From automotive to aerospace, these bearings serve as critical components, ensuring smooth operation and reliability in diverse operating environments.

|

In the automotive sector |

6206RS bearings are extensively utilized in various components such as wheels, transmissions, and engines. Their ability to withstand high speeds and heavy loads makes them ideal for automotive applications, where performance and durability are paramount. Renowned automotive engineer Mark Johnson asserts, The use of 6206RS sealed ball bearings in automotive systems enhances vehicle performance and safety, contributing to elevating industry standards. |

|

In the manufacturing industry |

6206RS bearings play a pivotal role in a wide range of machinery and equipment, including conveyors, motors, and robotics. Their high load capacity and precision engineering ensure efficient operation and minimal downtime, thereby maximizing productivity and profitability. According to manufacturing expert Sarah Lee, The reliability and durability of 6206RS sealed ball bearings are indispensable in modern manufacturing processes, where uptime and efficiency are critical metrics.

|

|

In the aerospace sector, |

where stringent performance requirements and safety standards prevail, 6206RS bearings are trusted for their exceptional reliability and resistance to extreme conditions. Whether in aircraft engines, landing gear, or control systems, these bearings contribute to the smooth and safe operation of aerospace equipment. Aerospace engineer David Smith emphasizes, The use of 6206RS sealed ball bearings in aerospace applications underscores their ability to meet rigorous performance criteria and elevate industry standards.

|

In conclusion, the versatility of 6206RS sealed ball bearings is evident across various industries, including automotive, manufacturing, and aerospace. Their reliability, durability, and performance make them indispensable components in critical machinery and equipment, thereby contributing to elevating industrial standards across diverse sectors.

4 Technical Specifications and Performance Metrics

The 6206RS sealed ball bearings stand out not only for their versatile applications but also for their impeccable technical specifications and performance metrics. These bearings undergo rigorous engineering and testing to ensure they meet the demanding requirements of industrial operations.

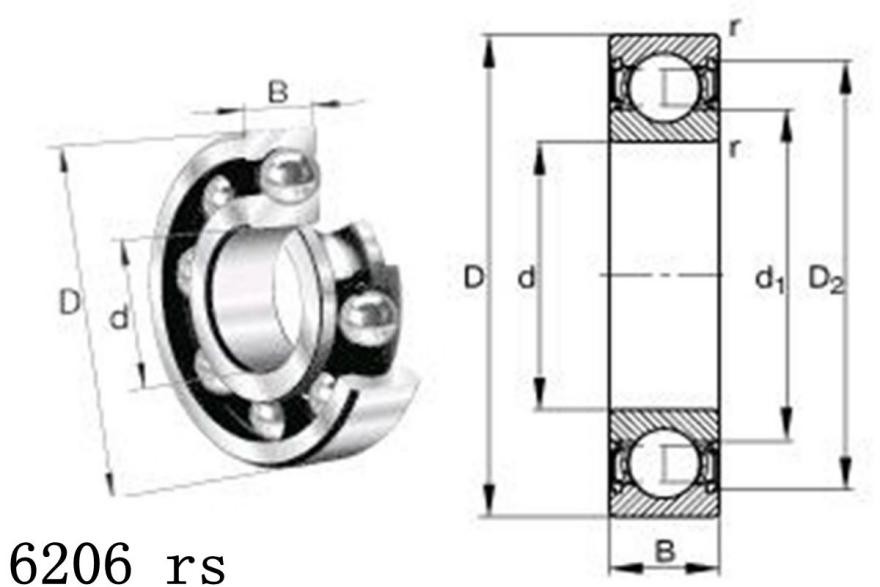

These bearings are standardized with a diameter of 30 millimeters, an outer diameter of 62 millimeters, and a width of 16 millimeters. Such meticulous sizing ensures compatibility across a wide range of machinery and equipment, enhancing their usability and interchangeability.

Moreover, 6206RS bearings boast impressive load ratings that enable them to withstand substantial radial and axial loads. With dynamic load ratings of up to 19.5 kilonewtons and static load ratings of up to 11.3 kilonewtons, these bearings are capable of supporting heavy loads while maintaining stability and reliability in operation.

In terms of speed capabilities, 6206RS bearings are engineered to perform exceptionally well even under high-speed conditions. With maximum permissible speeds of up to 11,000 revolutions per minute (RPM), these bearings ensure smooth and efficient operation in fast-paced industrial environments.

Precision engineering and material selection play a pivotal role in determining the performance of 6206RS bearings. These bearings are manufactured using high-quality steel and advanced sealing technologies to enhance their durability, reliability, and resistance to contamination. The use of precision manufacturing techniques ensures consistent and uniform performance, meeting the stringent requirements of industrial applications.

In summary, the 6206RS sealed ball bearings boast impressive technical specifications, including precise dimensions, high load ratings, and exceptional speed capabilities. Their performance is further enhanced by precision engineering and quality materials, ensuring optimal operation and reliability in diverse industrial settings. As mechanical engineer Robert Johnson affirms, The technical excellence of 6206RS bearings sets the standard for performance and reliability in industrial applications, underscoring their importance in elevating industrial standards.

5 Maintenance and Installation Guidelines

Proper maintenance and installation procedures are crucial for maximizing the performance and longevity of 6206RS sealed ball bearings. Following best practices ensures smooth operation, minimizes downtime, and prolongs the service life of these essential components in industrial machinery.

When it comes to installation, precision is key. Begin by thoroughly cleaning the mating surfaces and ensuring they are free from dirt, debris, and contaminants. Carefully align the bearing with the shaft and housing to prevent misalignment, which can lead to premature wear and reduced efficiency. Use appropriate tools and techniques to press or fit the bearing into place, taking care not to damage the seals or bearing surfaces.

Once installed, regular maintenance is essential to keep 6206RS bearings operating at peak performance. Implement a comprehensive lubrication schedule using high-quality grease or oil suitable for the operating conditions. Monitor bearing temperatures and vibrations regularly to detect any abnormalities that may indicate inadequate lubrication or potential issues.

In addition to lubrication, inspect the bearings and surrounding components for signs of wear, damage, or contamination. Replace worn seals, damaged cages, or any other components that may compromise the integrity of the bearing. Address any alignment issues promptly to prevent excessive loads and premature failure.

When troubleshooting common issues such as noise, vibration, or increased operating temperatures, systematically identify and address potential causes. Check for proper alignment, adequate lubrication, and any signs of damage or wear. Refer to the manufacturer's guidelines and consult with experts if necessary to diagnose and resolve complex problems.

By adhering to these maintenance and installation guidelines, industrial operators can ensure the optimal performance and longevity of 6206RS sealed ball bearings. As renowned maintenance engineer Lisa Adams emphasizes, Proper installation and maintenance practices are essential for maximizing the reliability and efficiency of bearings, such as the 6206RS, in industrial applications. By following best practices, operators can elevate industry standards and minimize costly downtime.

6 Conclusion

In conclusion, the 6206RS sealed ball bearings stand as exemplars of excellence in elevating industrial standards across diverse sectors. Their versatility and reliability make them indispensable components in modern machinery and equipment, contributing to enhanced efficiency, reliability, and safety in industrial operations.

Throughout this discourse, we have explored the myriad applications of 6206RS bearings in industries ranging from automotive to aerospace, highlighting their pivotal role in driving industrial innovation and progress. Their ability to withstand heavy loads, resist contamination, and deliver consistent performance underscores their significance in meeting the demanding requirements of industrial applications.

Moreover, the 6206RS sealed ball bearings play a crucial role in driving efficiency, reliability, and safety in various applications. By ensuring smooth operation and minimizing downtime, these bearings contribute to increased productivity and cost-effectiveness in industrial operations.

As we reflect on the importance of bearings in machinery and equipment, it becomes evident that 6206RS sealed ball bearings occupy a central position in elevating industrial standards. Their reliability, durability, and performance set the benchmark for excellence in modern engineering, reaffirming their status as indispensable components in industrial applications.

In summary, the 6206RS sealed ball bearings represent a cornerstone of industrial excellence, embodying the principles of reliability, efficiency, and innovation. Their versatility and significance underscore their importance in elevating industrial standards and driving progress in the ever-evolving landscape of modern industry.

7 FAQs: Common Questions About 6206RS Sealed Ball Bearings

Q1: How do I properly install and maintain 6206RS bearings?

A: Proper installation involves thorough cleaning of mating surfaces, precise alignment, and careful handling to prevent damage. Regular maintenance includes lubrication with suitable grease or oil and periodic inspection for signs of wear or damage.

Q2: What should I do if I encounter issues with 6206RS bearings, such as noise or vibration?

A: If issues arise, it's essential to diagnose the root cause by checking alignment, lubrication, and bearing condition. Consulting with experts and referring to manufacturer guidelines can help troubleshoot and resolve problems effectively.

Q3: Can 6206RS bearings withstand high speeds and heavy loads?

A: Yes, 6206RS sealed ball bearings are designed to withstand high speeds, with maximum permissible speeds of up to 11,000 RPM. They also have impressive load ratings, making them suitable for applications with heavy loads.

Q4: How do 6206RS bearings contribute to elevating industrial standards?

A: The reliability, durability, and performance of 6206RS sealed ball bearings contribute to increased efficiency, reliability, and safety in industrial operations. Their versatility and significance underscore their importance in driving progress and innovation in modern industry.

Q5: Where can I find more information about 6206RS bearings and their applications?

A: For more information about 6206RS sealed ball bearings and their applications, you can refer to manufacturer documentation, industry publications, or consult with experts in the field.

In summary, 6206RS sealed ball bearings are essential components in modern machinery and equipment, offering reliability, durability, and performance that elevate industrial standards across various sectors. Understanding their applications, installation, maintenance, and troubleshooting can help optimize their performance and contribute to efficient and reliable industrial operations.

USA VICKERS Pump PVH131R13AF30B252000002001AB010A

USA VICKERS Pump PVH131R13AF30B252000002001AB010A Parker Piston Pump 400481002108 PV140R1K1B4NWLZ+PGP517A0

Parker Piston Pump 400481002108 PV140R1K1B4NWLZ+PGP517A0 Parker Piston Pump 400481003286 PV180R1K1A4NYCD+PGP511A0

Parker Piston Pump 400481003286 PV180R1K1A4NYCD+PGP511A0 USA VICKERS Pump PVH057R02AA10B25200000100100010A

USA VICKERS Pump PVH057R02AA10B25200000100100010A Parker Piston Pump 400481004166 PV270R9K1B4NYLZK0033+PVA

Parker Piston Pump 400481004166 PV270R9K1B4NYLZK0033+PVA